Pimp my Rotring rapid PRO 0.5

This is a follow-up blog post to my earlier blog post about the Rotring rapid PRO 0.5.

The Rotring rapid PRO is a stunningly beautiful mechanical pencil, at least the black version is …for my taste. As you might remember the sliding sleeve was the worst performing sliding sleeve I have seen so far.

The purpose of a sliding sleeve

The main purpose of a sliding sleeve is, in my opinion, to slide back while you write so that you can keep writing without having to press the button / use whatever mechanism there is to advance the lead.

If the sliding sleeve doesn’t slide back easily you might as well got for a retractable sleeve, one that is either all the way in or out. This make the pencil pocket safe and allows work that is more suitable for drafting purposes, too.

On the unmodified rapid PRO 0.5 you had to use a force of about 1.2 N to get the sleeve to move – far too much to make the sleeve slide back automatically while you write.

Pimp my sliding sleeve

Having never explored how the sliding sleeve mechanism works I assumed ‘simple’ friction is responsible for the force needed to slide the sleeve. The problem is: I thought it’s the friction between the sleeve and grip section holding the sleeve (the grip section can be seen on the left in the first picture). To reduce the friction I took the sleeve out and started removing material from the sleeve on my Spyderco Sharpmaker. This made the sleeve thinner, something I had hoped would reduce the friction, but after a while I noticed that this treatment didn’t help making the sleeve slide easier at all.

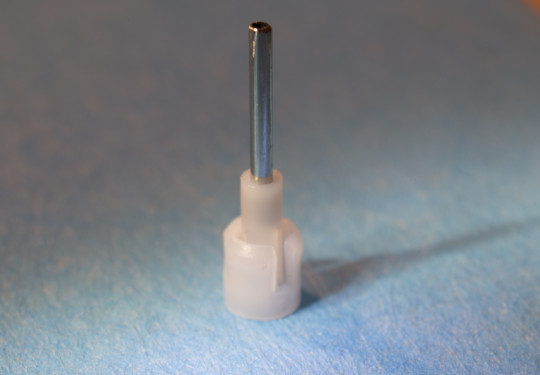

I then figured out that the friction holding the sleeve in place must be caused by the white plastic holder at the bottom of the sleeve. I started using the file from my Swiss Army knife [1]Fun fact: I got this knife from my godfather in the 1980s and I believe it is the same model as the one that the astronauts used on the Space Shuttle, just mine has a cork screw instead of a screw … Continue reading to remove some of the plastic, i.e. making the plastic holder narrower, but that took too long, so in the end I just cut bits of the plastic off with the knife.

This time it worked. Great!

From 1.2 N to 0.2 N

The result: You now only need about 0.2 N to slide the sleeve of my rapid PRO, which makes it suitable for writing without having to advance the lead all the time. This is an amazing result – because of the bigger lead diameter you can’t compare an 0.5 mm sleeve directly to the 0.2 mm sleeve of the Orenz. Just the friction caused by the 0.5 mm lead in the rapid PRO’s sleeve (i.e. just these two parts, ‘outside’ the pencil) means that you need 0.1 N just to slide the sleeve down the lead – that’s without the additional force needed to slide the sleeve within the pencil barrel/ grip section.

If I’d have to do it all again I obviously wouldn’t make the metal sleeve narrower. It made the sleeve a bit more wobbly, but it is not really an issue. It is certainly still less wobbly than a Kuru Toga or Muji’s flat clip mechanical pencil.

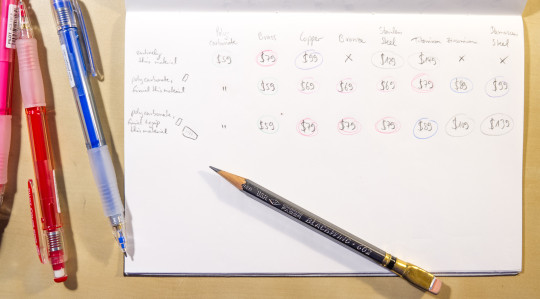

![That's one small scrape off [a] sleeve, one giant leap in the friction chart.](https://bleistift.blog/wp-content/uploads/2015/10/pimpmyrotring5-540x405.jpg)

More about the Cloud Book in the blog post, I’m still using it regularly.

References

| ↑1 | Fun fact: I got this knife from my godfather in the 1980s and I believe it is the same model as the one that the astronauts used on the Space Shuttle, just mine has a cork screw instead of a screw driver. |

|---|

Pimp my Rotring rapid PRO 0.5 Read More »